BodyHoliday St Lucia, owned by Sunswept Resorts, is set on a secluded cove of white sandy beach at the edge of the Caribbean Sea and surrounded by tropical gardens and rainforest. It’s the ultimate getaway for body and mind, recognised as one of the finest destination resorts and a centre of well-being.

With six five-star restaurants designed to satisfy every taste, featuring menus using locally-sourced foods and ingredients fresh from the resort’s own organic gardens, the kitchens are one of the focal areas of the hotel and formed part of a recent $20 million renovation, completed just in time for the property’s 30th anniversary. Covering an area in excess of 250m2 and subdivided into sections including an allergy kitchen, bringing these areas up to standard was an integral part of the refurbishment plan.

Resin flooring – matching the demands and performance requirements

The project was completed by industrial flooring specialists Zircon Flooring, based in Yorkshire, who specified Pumadur products by Resdev as the ideal solution to match the aesthetic and performance specifications for this prestigious project. These durable products, offering the perfect combination of impact, abrasion and chemical resistance perfect for catering flooring. They also yielded the application characteristics necessary for this hot tropical environment.

Durable food grade resin flooring systems were the obvious choice for this food preparation area, where resistance to steam cleaning and pressure washing processes was an essential performance requirement. Pumadur systems have been used across the world for applications including Bella Fresh Foods in the USA.

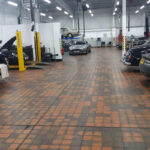

Quarry tiles covered the existing industrial kitchen floor

The team from Zircon Flooring began by removing the existing kitchen quarry tiles before diamond grinding and undertaking repairs to level the floor using Resdev Pumabulk. Movement joints were installed using Resdev’s Pumexpand P.

Resdev Pumadur systems used for the new commercial kitchen flooring

Pumadur RT was then applied to all areas. Pumadur RT is a resin-rich heavy duty, trowel applied polyurethane floor screed providing the highest order of durability, impact, abrasion and chemical resistance, with a lightly textured finish making the product ideal for both wet and dry processing environments. Easier and quicker to apply than stiffer screeds, Pumadur RT is stable to steam cleaning and hot water exposure and is seamless, non tainting and with the textured finish results in non slip kitchen flooring.

Zircon Flooring rendering covings in the kitchen

Zircon Flooring also installed covings using Pumadur WR, a polyurethane wall render, coving and upstand system with a matt finish, designed for use with Pumadur polyurethane flooring systems to give a totally seamless ‘box’ finish for high hygiene food processing. This work was completed with the application of a seal coat to the covings using Pumadur TF.

Closeup of the Pumadur flooring and coving detail

A clean, light and bright working environment

From the outset, this was a demanding task which would require skill, expertise and the correct product specification to ensure the optimum outcome. Temperature and humidity levels in St Lucia (36-40° during daylight hours) presented real challenges in terms of storing, installing and curing the products selected for the work.

Selecting a light, bright colour for the floor across all areas has successfully created a pleasant working environment where light is optimised. In addition, carrying the same colour and finish throughout all the different areas of the kitchens has added to the feeling of light and space in every room.

Detail of the catering flooring with drainage

The end result is a clean, fresh and practical industrial kitchen flooring system, using resin flooring to its best advantages, successfully transforming what was a tired and jaded food preparation area into a bright, airy space reflecting the calibre and high standard of the food served.